Automatic sandblasting machine aims to replace manpower to increase production capacity and improve finishing quality, a good solution to creates uniform and clean surface.

Automatic blasting machine is designed with various types to meet different workparts and applications. Here I introduce several models that frequently used on the market.

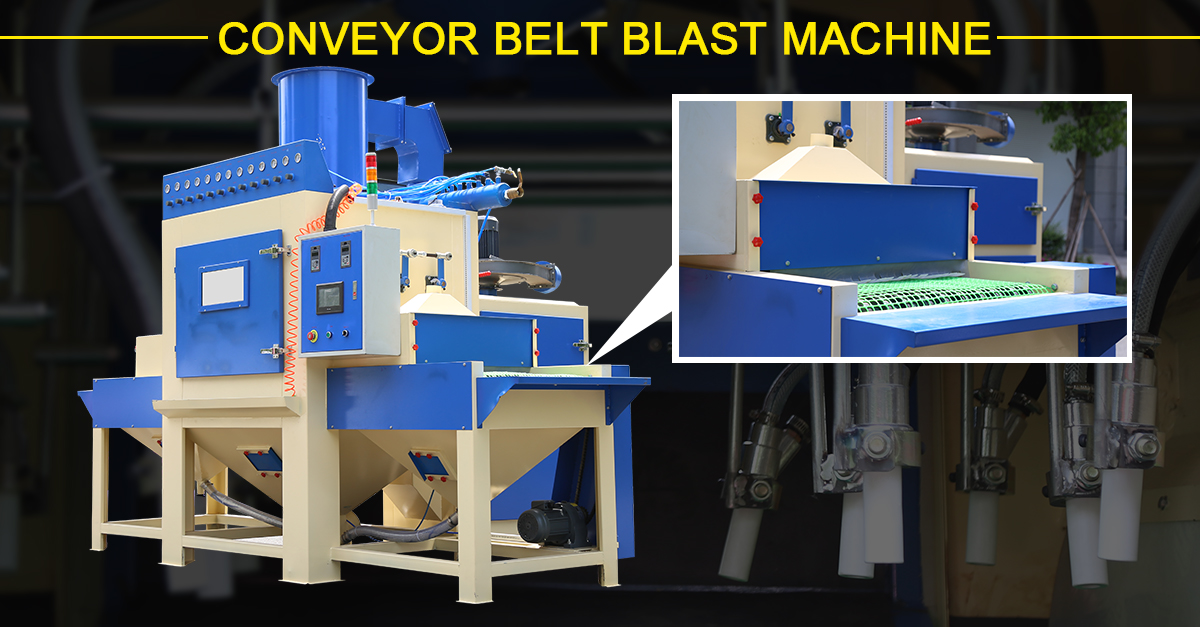

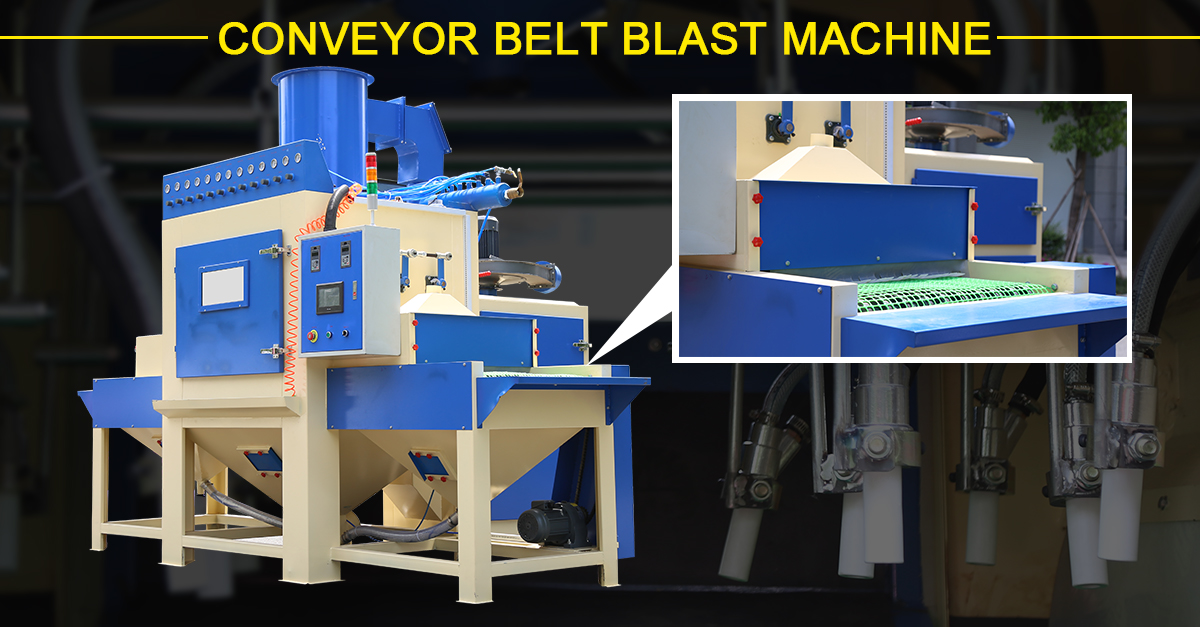

Application: flat parts, such as mobile phone shell, metal plate, profiles, computer keyboard, note book shell, ceramic tile, discs, etc.

Features, put batch products on the continuous belt, automatically transporting to working station for automatic blasting. The quantity of auto-gun can be customized and the gun position can be adjusted based on actual condition

Application: small parts, such as screws, zippers, plastic and metal accessories. Usually for deburring, cleaning, rust-moving, etc.

Features: a built-in automatic tumble basket holds a large quantity of small parts, the parts tumble while the basket rotates, ensures each part is completely blasted by automatic blast gun.

Application: Big, heavy, irregular shape workpiece, such as statue, alloy wheel, mold, etc. Reduce manual efforts to do tough jobs more effectively and perfect

Features: The turntable is designed for automatically rotating, the blast gun is fixed to work automatically.