Wet sandblaster use a slurry pump to produce a highly mixture of abrasive and water, the pump directly push the mixture to the blast gun with compressed air then blast to the product surface, attain the purpose of removing rust, oxides, contaminants, old coatings, etc.

The wet blaster is used to clean the rough surface of metal, rubber and plastic products, can be applied to derusting, degreasing. descaling, deburring. It is also recommended or pre-treatment

of the powder spraying, painting, plating process, In order to improve the surface adhesion. For spray glass beads, strengthen and decorate the surface of parts.

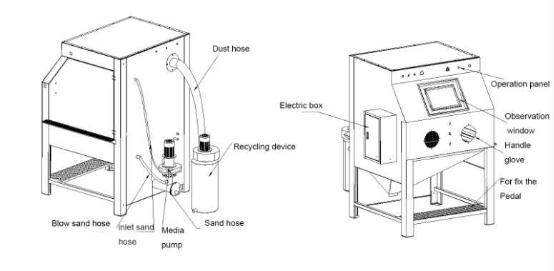

The inner wall of the blasting cabinet is covered with rubber, in order to reduce wearing and improve equipment life.

A Blasting gun with a 8mm boron carbide nozzle, is not fixed, can add a fixed device if need. It can adjust the blasting distance, angle and location per need.

The machine is equipped with a perspective window for the observation of wet blasting working conditions.

1.Power start: after connected to power, the indicator light will shine.

2.Before start the machine, please add water to the cabinet first.

3 Load abrasive When load the abrasive, must be open the dust collector fan motor, load slowly, load proper and suitable weigh abrasive.

4.Sandblasting Operation: After all the prepare works are completed, check the pneumatic supply. Close the hatch, into the working position, respectively, hold products and spray gun, stamp the "foot switch 1" into the processing state.

1. Be sure to close the door before starting the job, to ensure that the energy supplies reliable, appropriate.

2. The operation process, the glass window may be mist, sand and dust cover, resulting in blurred vision, this time can be stepped on the foot "switch 2" to start the nozzle, water spray cleaning glass (wiper will start cleaning glass ). And according to the need to adjust the "delay relay" to set the nozzle and wiper reasonable working time. If necessary, replace by the see-through glass.

3. Such as the use of water jets to clean the product, the overflow will be injected into the cabin at this time overflowing the amount of water out of the machine. Please treat the overflow the sewage reasonably.

4. Regularly clean inside the water and sand and dust of the demister. (Cleaned every 8 hours)

5. Please regularly check the wear accessories, replace if need.

6. In case of emergency, press the "emergency stop" (marked) button. Will cut off all use of power equipment, including lighting.

7. When complete the job, please turn off all power, pneuma, water, then clean and maintain equipment.

See product page to know more details about wet sandblaster.