Vibratory finishing machine have an action that is similar to grinding. The grinding media surrounds the workparts.. A rotating weight shakes the containter in a circular path during which the entire load is lifted up at an angle and then dropped. In this case, medias and workparts rub against each other causing a cutting action.

Vibratory finishing systems tend to produce a very smooth flat finish because it really laps the parts. Since the load is moving as a unit, very fragile parts are quite safe in a vibrator. There is no tearing action or unequal forces that tend to bend and distort parts.

If you are looking for those basic smoothing and polishing purposes, you can choose a vibratory tumbler. The tumblers according to the demands has various designs:

Round Bowl Vibratory Finisher

Suitable for small workparts in very small scales or big sized workparts, which should be easy to manually selected the items after tumbling finish.

Curved Bowl Vibratory Finisher with Separator

Suitable for relatively small and hard workparts, as the curved wall design creates higher cutting force, the separator allows automatic screening small workparts from tumbling medias.

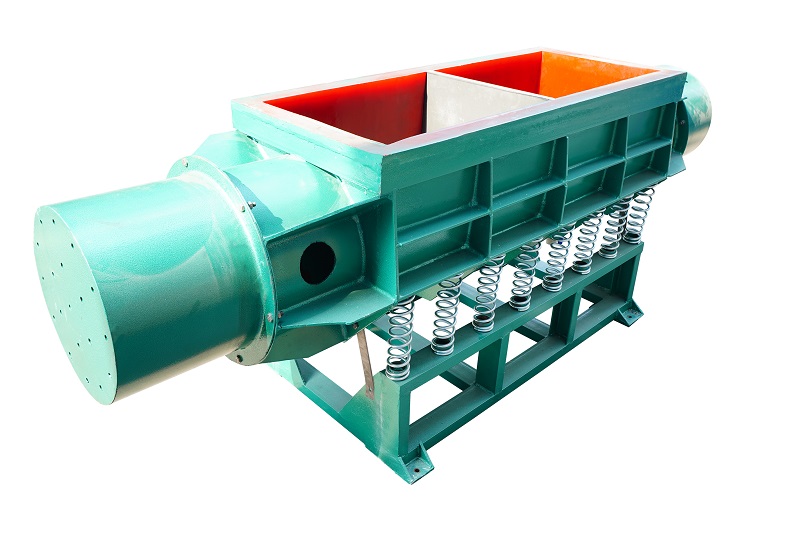

Tub Vibratory Finisher

Tub type vibratory finishing machine is ideal for long length or big shape workparts, the tub chamber length can be designed up to 2 meters or more.