Vibratory finishing achieves rough or precision treatment for parts processing, such as removing unwanted burrs, smoothing sharp edges, creating bright and new surfaces, while the tumbling media acts a vital role to attain those purposes

The material, shape and size of media all determines the effect your want. Choosing the right finishing media optimizes the quality of your finished product while providing cost-effective, mass-produced results.

Here is a brief introduction for common-used tumbling medias

1. Aluminum Oxide Deburring Media

Brown aluminum oxide media is the most widely-used media for deburring purpose but without polishing effect. Its dense texture and high hardness causes excellent cutting performance and low wear rate, durable enough for grinding finish with various metal or non-metal parts.

2. Plastic Deburring Media

Plastic Media normally has a polyester resin base, which is formulated to create smooth surface especially for softer metals, such as brass, aluminum, zinc. It is available in low density, high density that offers light to heavy cutting action. an ideal finishing media for deburring, edge rounding for soft metal or plastic materials.

3. Ceramic Tumbling Media

Ceramic tumbling media for mass finishing is formulated for general purpose polishing, light and heavy deburring Ceramic media is highly durable and long lasting, offering fast and aggressive cutting action for shorter cycle times. It is best choice for harder metals such as steel and stainless steel.

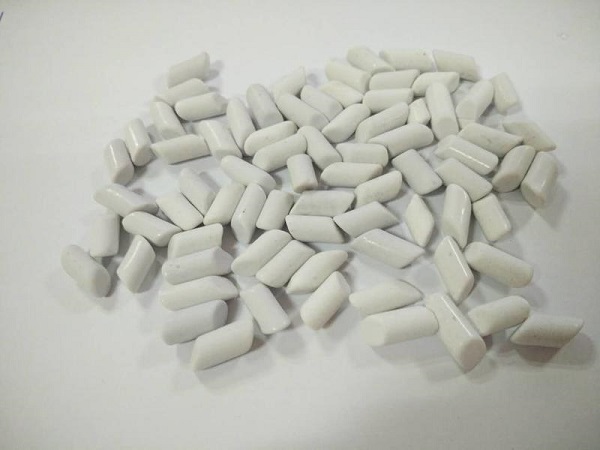

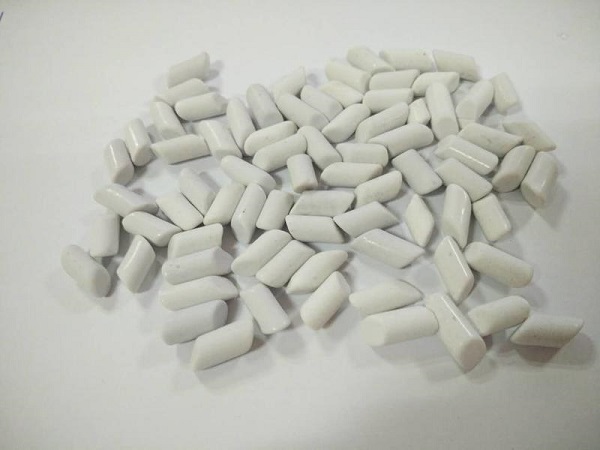

4. High frequency Porcelain Media

High frequency Porcelain media is designed for specific applications where precision deburring and polishing is required. It offers fast and aggressive cutting action, suitable for metal, plastic.Porcelain tumbling media is extremely durable for long lasting use, which reduce operating cost.

5. Stainless Steel Polishing Media

Stainless steel media is used to polish or highly polish parts with bright and smooth surfaces. Stainless steel media is a non-consumable media. Its rust inhibition property makes it easy to store in longer term, and Its durability effectively reduces finishing times. Not only get the burnishing effect, parts processed with steel media have longer cycle lives and greater resistance to wear.

6. Zirconia Oxide Polishing Beads

Zirconia bead is the very ideal media for precision polishing of hard metal parts, whose high density ans toughness offers quick and aggressive grinding, creating surfaces with high brightness and smoothness. Zirconia beads are extremely durable that hardly get broken or cracked, the low self-wear rate makes long lasting use that saves your handling cost.

Tumbling media comes in a range of sizes and shapes, from cylinders and balls to triangles, pyramids and sharp-edged stars. Choosing the shape of the finishing media often depends the finishing results you required.

For general use, ball or cylindrical media is preferred, as rounded surfaces is more wear-resistent with much lower chipping rates, even better, they have less chance of lodging in parts than sharp wedges.

Triangles, pyramids and tri-star shapes tends to provide more aggressive cutting action, as they are better suited for stripping burrs or unqualifies layers, but they come with higher wear rate and are more likely to chipping.

For size, smaller medias get more contacts on surfaces and finish in low speed, which create finer effect, while larger media provides rapid removal of burs and shape egdes.

Kafan mass finishing tumbling media - we can guarantee the right shape, size, and composition to rightly fit your vibratory finishing requirements. Just contact with us for your solution!