Wet blasting is one of the most modern technologies for finishing and cleaning surfaces with highest quality. Kafan closed loop wet blast cabinets deliver the unique benefits of surface treatment technology.

The main advantage of a closed loop wet blast systemis it does not require a running water supply to operate, which only requires a compressed air supply and a power source to operate. Once you add abrasive and water to the cabinet, you recycle them until you want to change it out.

Why choose a closed loop wet blasting system?

Some workshop might need a closed loop system because running water is not available there. If it is inconvenient to run a hose to the wet blast cabinet for running water, a closed loop system is a good choice.

Another reason a facility may want a closed loop system is worrying about waste water disposal, or properly disposing of spent abrasive, this may be another reason to add a closed loop to your wet blast cabinet.

How closed loop vapor blasting cabinet works?

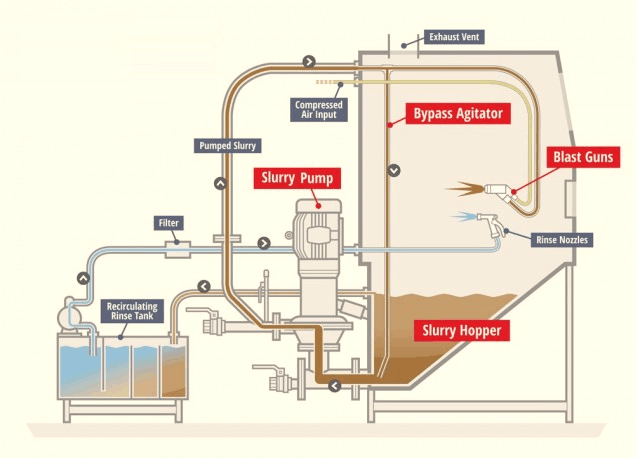

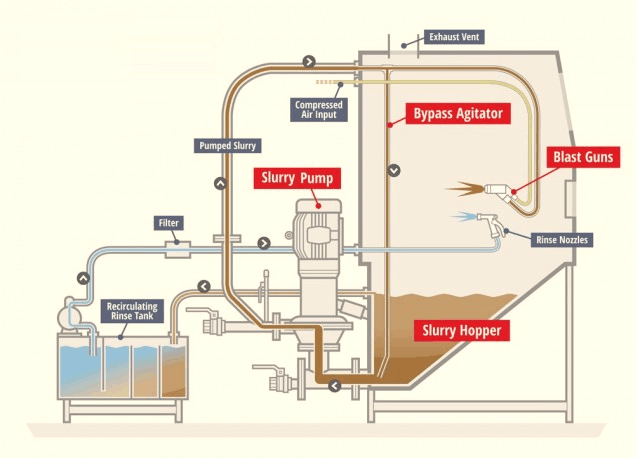

Closed loop vapor blaster has a baffled settling tank interconnected to the slurry hopper for water recirculating

The interconnecting point in the hopper is at the very top level of the slurry, which has minimal amount of media particles suspended in it, thus more water can be conveyed to the tank and more abrasives settled in the slurry hopper for recycling.

The baffled settling tank is designed to create a weir-like path for the water flow, slowing down to allow the solid particles settling to the bottom.

A rinse pump is placed at the end of the baffled settling tank, which draws water from the tank and delivers it to the rinse spray nozzle through a filter. Whenever the clean rinse water is released into the blast cabinet, it creates an overflow condition of the slurry hopper, so an equal amount of water drains back to the settling tank, thus forming a closed loop system, all water and abrasives are recirculated.