Car Brake Calipers or Motorcycle Brake Calipers may look bad but work fine, they are just rusty or covered in dust. We suggested that you restore them, have them sandblasted and paint them, they will get brand new surfaces. Sandblasting is a good method of getting calipers clean enough and for powder coating adhesion, effiectly removing heavy rust, old paints, or deep scratches.

Removed brake calipers from the car but not disassembled, with the fitting holes plugged, they can be effectively sandblasted. The sand blasting will not harm the boots or other rubber parts. While off the car they then should be disassembled and cleaned internally before painting and reinstalling.

Kafan supply complete finishing systems for refurbishing brake calipers from sandblasting to powder coating, we offer all sizes and styles for your every needs and can customizes for special requirements.

For manual sandblasting, we recommend wet blast cleaning, as this process creates a finer and dustfree surface..

Wet blasting cabines use a slurry pump agitating media and water into a slurry mixture. it introduce water into the air stream which is good for dust control. No abrasive impregnation into the part's surface that is very clean. Water borne abrasive cushions the cleaning process, giving a finer and higher quality finish, especially for delicate or precise products.

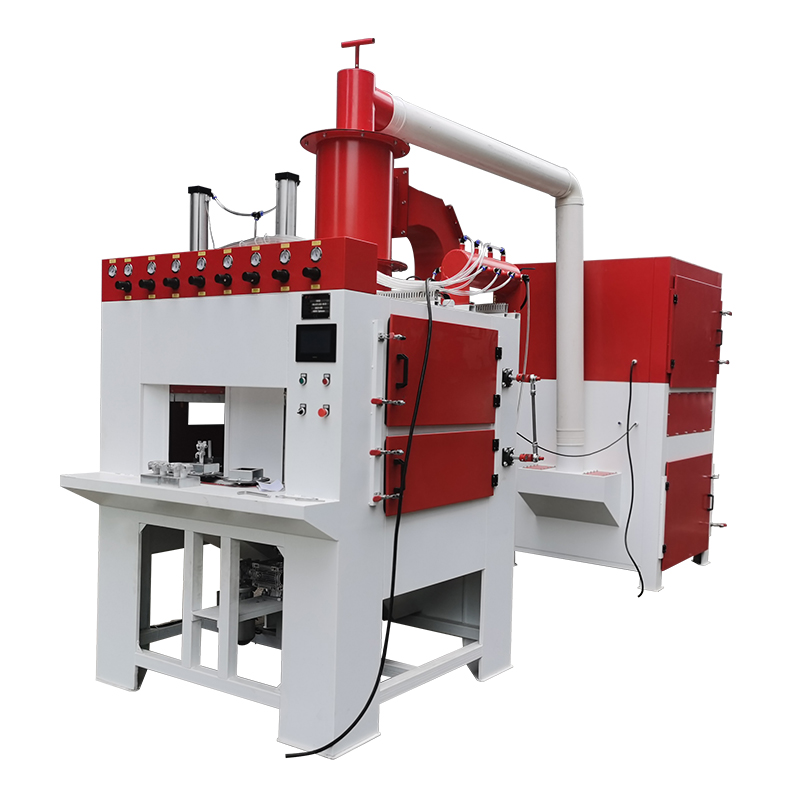

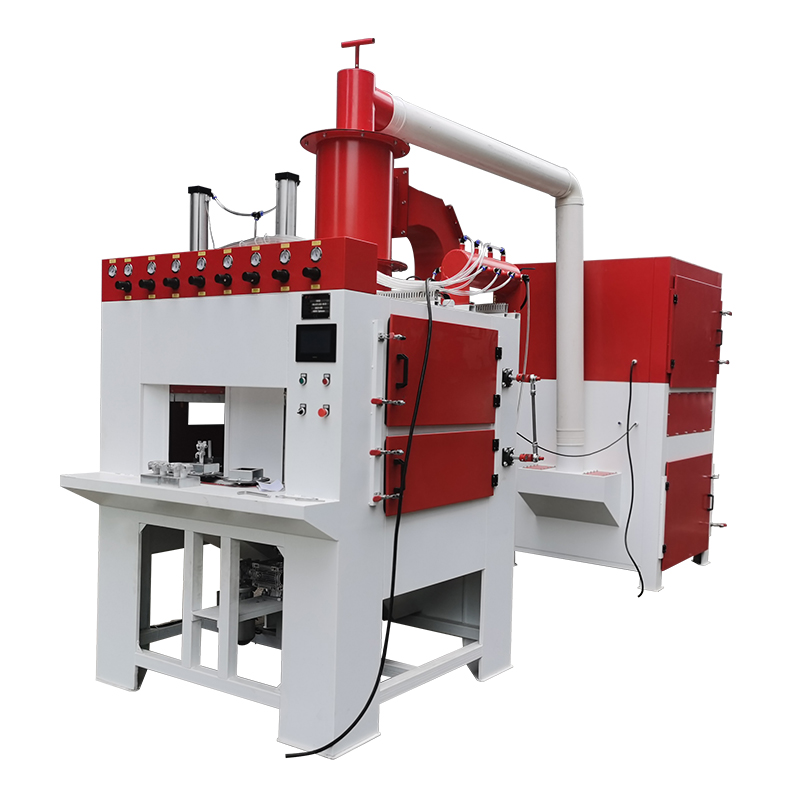

For automatic sandblasting, we have an extraordinary indexing rotary sand blasting machine for more uniform cleaning and higher output.

This automatic blasting system is configured with a large indexing table and fitted with multiple spindles inserted with brake calipers. The indexing table intermittently rotates to present the workparts in front of the automatic blast guns, while each spindle rotates itself ensure all the surface to be cleaned. Built with the increased capacity afforded by multiple spindle options, the spindle quantity can be customized.

3. For powder coating, we have complete powder coating system for brake calipers.

The equipment package includes powder coating gun, spray booth and curing oven giving an easy and quick start of powder coating application. The powder coating gun offers beautiful, smooth powder film and easy penetration into corners, the spray booth efficiently recover powder overspray, keeping a dustless working condition, the curing oven quickly heats powder coating results in a durable coverage.