Sandblasting Wheel Rims and Shot Blasting Wheel Rims are the two of the most popular surface treatments. Now lets have a lesson of what is sandblsting and what is shot blasting?

Sandblasting powered by compressed air forms a high-speed stream to spray the abrasive media onto the surface of the workpiece, so that the mechanical properties of target surface will be changed, and obtains a certain degree of cleanliness and roughness.

While Shot blasting applies centrifugal force from a mechanical rotating impeller to propel small steel shots or small iron shots upon the surface of the part at high speeds, so it can remove the oxidation on the surface of the part and layer, increasing product adhesion.

Sandblasting and Shot Blasting Differences:

Sandblasting and Shot Blasting Differences:

1. The power source.

Sandblasting machine powered by compressed air, while shot blasting machine employs electricity to centrifugally accelerate shots under the help of a device similar to a spinning wheel.

2. The abrasive media

Due to sandblasting is usually applied to achieve delicate surface, so light and thin abrasives are more suited, like glass beads, quartz sand, corundum, aluminum oxide, plastic sand etc.

Shot blasting is designed with a pressurizing system for larger and more difficult preparation objects. So it needs denser abrasive to form strong force on the surface. Steel shot, stainless steel girt or other similar heavy shot are appriporiate application.

How to choose sandblasting or shot blasting for alloy wheels?

1. The surface effect you required

Shot blasting is much more aggressive than sandblasting, so it will give rougher surface than sandblasting technology. Sandblasting is considered preferentially if excellent quality of the wheel surface is required, usually making it smooth and delicate.

2. The productivity and the cost

There are several options for alloy wheel sandblasting machine, manual blasting machine or automatic alloy wheel blasting machine. The period to finish blasting one piece wheel is about 15 minutes varying from wheel sizes. Automatic alloy wheel blasting machine cost doesn't exceed USD5000 as usual. And manual sandblasting machine is much lower cost. This is quite economical investment for some new coming workshop.

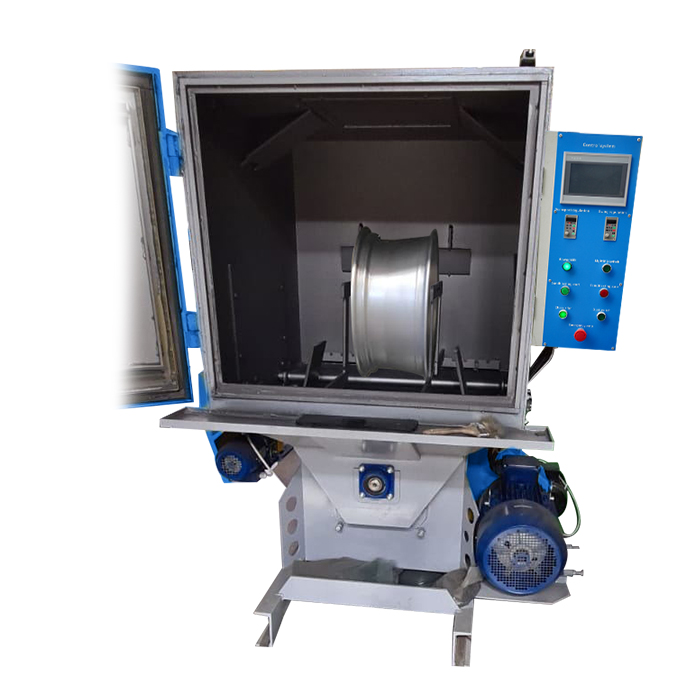

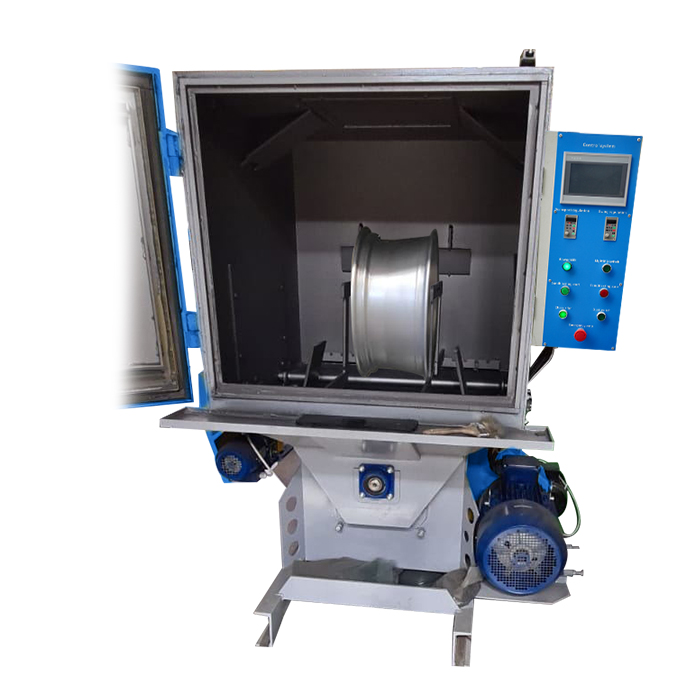

While shot blasting machine for alloy wheel is more expensive, which costs USD10000 or more. But it is more efficient for processing wheels, about 2 or 3 minutes to get a finshed wheel with shot blasters.

Anyhow, sandblasting is still a more common application for wheel cleaning and finishing, as there's more options on abrasives and on blasters, such as dry type, wet type and pressure type. Sandblasting is also easier to operate. Consumers can choose preferred machine according to their own situation.

Sandblasting and Shot Blasting Differences:

Sandblasting and Shot Blasting Differences: